Based on CISSOID SiC inverter control modules (ICMs), providing a wide range of voltage and power, the reference design can support up to 850V operating bus voltage and 350kW power output, achieving an excellent power density of 52kW/L (60s peak power).

Vehicle Inverter Reference Design

A high power density, easy to configure EVK-PLA1060A series vehicle inverter reference design has been developed, making production readiness a step further. Targeting in-vehicle and field testing, these reference designs correspond to B/C-sample level functionality, further accelerating time to market and reducing the engineering effort required to implement a functional electric drivetrain. Based on CISSOID SiC inverter control modules (ICMs), providing a wide range of voltage and power, the reference design can support up to 850V operating bus voltage and 350kW power output, achieving an excellent power density of 52kW/L (60s peak power).

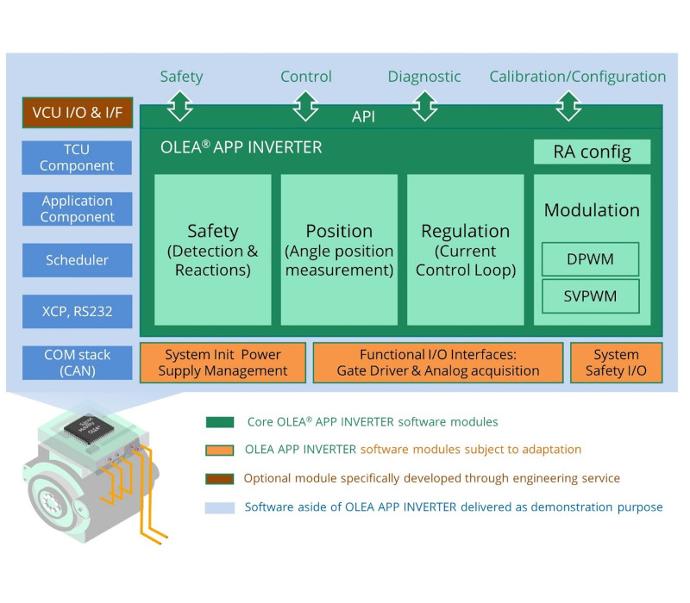

Certified real-time processor and software The control board in the inverter control module used in the reference design is based on an application-specific processor Mobility by the Silicon, namely OLEA®T222 Programmable Control Unit (FPCU). OLEA®The T222 FPCU is equipped with programmable hardware to accelerate response time to critical events, offload processor cores, and enhance functional safety. The platform provides highly configurable control application software that supports various types of motors and position sensors.

OLEA®APP-T222 INVERTER is for OLEA®The T222 FPCU parallel architecture is designed with embedded software to achieve high-performance, real-time control. It provides efficient and safe torque, speed, current and rotor control using advanced algorithms. This multifunctional software is suitable for various application fields, supports the latest technology inverters, and uses parallel hardware to realize fast control loops. It also includes a separate functional safety stack that supports model-based design flows for seamless integration.

OLEA®T222 FPCU and OLEA®APP-T222 INVERTER software is ISO 26262 ASIL C/D certified and meets AUTOSAR 4.3 standards.

▪Field Oriented Control (FOC)

▪High control loop and switching frequency (up to 50kHz)

▪Advanced modulation techniques (space vector pulse width modulation (SVPWM), discontinuous pulse width modulation (DPWM))

▪Weak magnetic expansion function

▪Optimized Dead Time Compensation

▪Improved Total Harmonic Distortion (THD)

▪Reducing Voltage Ripple of High Voltage DC Bus

• OLEA®T222 Processor and Software: Certified by ISO26262 ASIL-D and AUTOSAR 4.3

▪ inverter control module: Designed to meet ISO-26262 ASIL-D standards (under certification)

▪1 programming and configuration interface (Lauterbach tracking interface)

▪1 SWD debug interface

▪1 CAN flexible data rate interface up to 8 Mbit/s

▪1 CAN high-speed interface up to 1 Mbit/s

▪1 motor temperature measurement interface (support PT100/PT1000/KTY84 and NTC sensor, including signal conditioning circuit)

▪1 resolv interface (excitation/sine/cosine)

▪1 battery input connector

▪1 HVIL (high voltage interlock) input interface

▪2 digital input signal interfaces

▪1 digital output signal interface

▪Spare: 1 analog or digital input signal interface

▪1 USB interface

▪1 quadrature encoder interface (A/B/I)

▪Three digital Hall-effect interfaces

▪Five analog input signal interfaces

▪Six digital input signal interfaces

▪6 relay interface digital outputs

▪2 auxiliary 5V power connectors

Specifications

| Inverter characteristics | Parameters | Unit |

| DC Bus Voltage-Operating | 100 to 800 | VDC |

| Maximum DC bus voltage Non-working state |

850 | VDC |

| Maximum phase current-steady state -Amphenol HVSL1 three-phase connector -TE HVP-HD1400 three-phase connector |

250 320* |

ARMS |

| Maximum phase current-peak (60 seconds) | 565 | APEAK |

| Maximum Output Power-Steady State -Amphenol HVSL-1000 three-phase connector -TE HVP-HD1400 three-phase connector |

245 300* |

kW |

| Maximum output power-peak (60 seconds) | 350 | kW |

| Output frequency | 100 to 2000 | Hz |

| Inverter PWM Frequency | 10 to 50 ** | kHz |

| DC Link Capacitor | 135 - 500 | μF |

| DC bus discharge time (passive) | <60 | s |

| Vehicle battery voltage supply | 6 to 36 | VDC |

| Operating temperature range (coolant) | -40 to 65 | °C |

| Coolant flow | 2 to 20 | Litre/min |

| Three-phase connector (Amferno HVSL1000023A1H8) |

IP69K / 1kV / 250A WHITES |

|

| Battery Connector (Amferno HVSL1400022A1D8S6) |

IP67 - IP6K9K / 1kV / 430A WHITES |

|

| Dimensions (shape) | 381x220x90 | mm |

| Dimensions (volume) | 6.73 | l |

| Power density (steady state) | 36 | KW/litre |

| Power density (60 seconds peak) | 52 | KW/litre |

| inverter peak power efficiency @ 210kW, 700V, 275ARMS, 10kHz @ 50kW, 700V, 100ARMS, 10kHz |

> 99 99.1 99.6 |

% |

* Design modifications required

**Output power derating versus PWM frequency

Application:

-Electric vehicle (EV) motor drivers

-Heavy duty motor drives (off-road, road and industrial)

-Avionics and marine motor drives

-High performance motor driver

-Industrial motor drives