Behind cross-border transport fleets, smart tracking devices and industrial IoT systems, there is an often overlooked but vital component-the SIM card connector. It is this tiny and sophisticated hardware that supports the continuous communication of IoT devices around the world in extreme environments. AsIndustry-leading distributor of electronic components,BonChipProvide customersFull range of SIM connector products, best price and fast delivery service, to help enterprises build high-reliability IoT solutions.

When a cargo truck travels through three countries in a single day, and sensors in precision pharmaceutical cold chain boxes record temperature fluctuations every 0.1°C in real time, the core capability of these devices is based on the same foundation: stable and reliable cellular network connectivity.

In the field of the Internet of Things, people usually focus on AI algorithms, hardware design and cloud platforms, but it is the unknown SIM card connector that really ensures that the device continues to be online on a global scale. It not only physically fixes the SIM card, but also undertakes the key tasks of device authentication, secure connection establishment and data transmission. A high-quality connector can maintain stable electrical contact under severe vibration, extreme temperature and harsh conditions of long-term use.

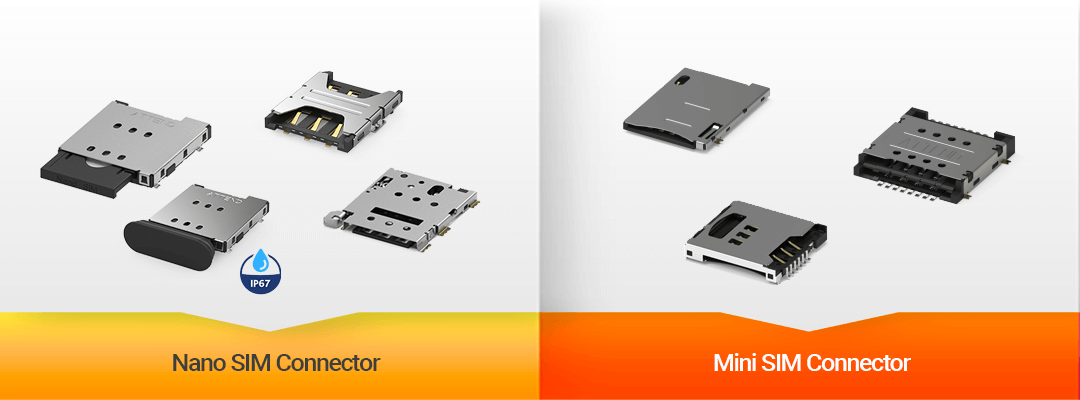

In-car system: Strong fortress of Mini SIM connector

In equipment such as AI dash recorders and fleet management gateways that are equipped with commercial vehicles,Mini SIM(2FF) connectorWith its larger size brings significant mechanical stability advantages. These devices experience continuous road vibration, temperature cycles of -40°C to 85°C, and sudden shocks. The robust design of the Mini connector ensures connection reliability in harsh driving environments, providing a solid foundation for real-time video streaming, driver behavior analysis and emergency alert delivery.

Asset Tracking: The Precision Art of the Nano SIM Connector

For tracking equipment that needs to be placed in freight containers or high-value goods,Nano SIM(4FF) connectorIt is ideal for its extremely small PCB footprint (60% less than Mini SIM). These tiny devices need to last for months or even years on a single charge. The Nano connector provides enterprise-class cellular connectivity while maintaining the perfect balance of low power consumption and space efficiency.

Fleet Management: Guardians of Safety and Efficiency

Modern commercial vehicles have evolved into "wheeled data centers". The AI driving recorder not only records video, but also analyzes the driver's state in real time, identifies dangerous following distances, and even predicts potential accidents. All of these smart functions rely on the continuous two-way communication ensured by the SIM connector-it handles both upstream video streaming and downstream firmware updates, route adjustments and emergency notifications. In an industry where a single preventative incident can save lives and millions of liability, connector reliability has been upgraded from a "preferred" to a "must have".

Asset tracking: full visibility and status monitoring

Modern logistics has evolved beyond simple parcel positioning to full status monitoring. Is the refrigerated container maintained at the right temperature? Has the cargo experienced abnormal vibration? Has the seal been broken? These key data are transmitted back in real time through the tracker with the built-in Nano SIM connector. When pharmaceutical companies transport temperature-sensitive vaccines across borders, it is this tiny connector that ensures product integrity monitoring that guards the effectiveness of each dose.

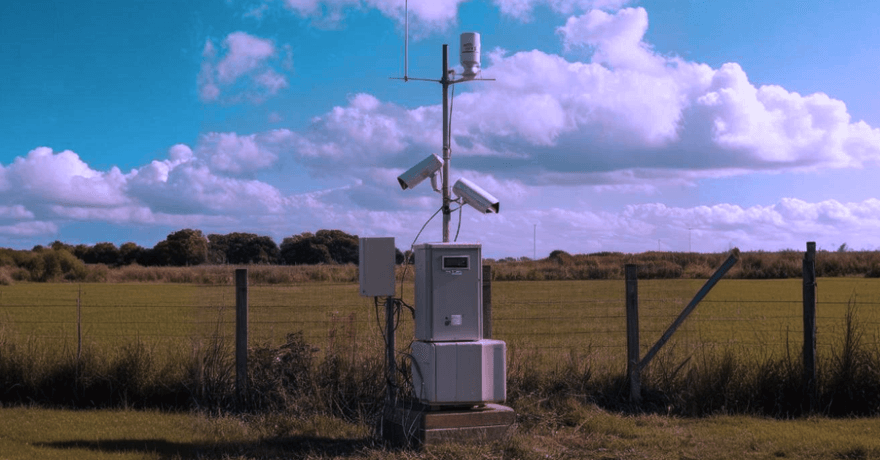

Industrial Internet of Things: Reliability Test for Long-Term Deployment

From smart meters that report energy consumption, to industrial sensors that monitor the health of equipment, to remote environmental monitoring stations, countless IoT devices may operate continuously for ten years after deployment without human intervention. The SIM connectors in these scenarios must be "one-time deployment, long-term reliability" and continue to perform connection duties in an unattended environment.

Vibration resistance

Vibration resistance

High-quality connectors are designed for specific application environments, and can withstand the vibration characteristics of different scenarios such as highway driving and off-road equipment operation, and maintain stable contact.

Temperature Cycle Adaptability

Temperature Cycle Adaptability

Special materials and structural design are used to ensure that contact pressure is not lost during extreme temperature cycles, avoiding corrosion in humid environments or embrittlement in severe cold.

Insertion and extraction durability

Insertion and extraction durability

A good connector needs to withstand thousands of cycles during manufacturing, testing, and field service, while maintaining consistent electrical contact performance. The spring tension needs to be accurately calibrated-too loose will cause the connection to be interrupted, too tight may damage the SIM card.

Protection level compatibility

Protection level compatibility

Most industrial Internet of Things applications require equipment to have IP67/IP68 protection level, and excellent SIM connectors can meet dust and waterproof requirements without increasing design complexity or volume.

Mini SIM(2FF) connector-preferred for in-vehicle systems

Excellent mechanical stability, strong resistance to vibration and impact

Reliable contact for high data transmission scenarios

Ideal for: driving recorder, fleet management hub, vehicle gateway

Nano SIM(4FF) connector-the perfect solution for asset tracking

Ultra-compact design saves PCB space

Low power consumption features, extended battery life

Ideal for: logistics trackers, cold chain monitoring, portable medical equipment

BonChip supply advantage:ATTENDAuthorized distributors of leading connector manufacturers, we provideATTEND full range of SIM connector productsFrom standard specifications to customized solutions to meet the specific needs of different industries. OurTechnical TeamCan help customers choose the most suitable connector model,Optimize material costs and accelerate time-to-market。

Although eSIM technology has made progress in consumer electronics, the physical SIM card still maintains significant practical advantages in industrial IoT deployments:

Ease of operation

The equipment of logistics companies often moves between countries in Southeast Asia, facing different operators, network conditions and regulatory requirements. When a carrier needs to be changed, the physical SIM card can be replaced in minutes by an on-site technician, while eSIM involves remote configuration systems, carrier cooperation and potential compatibility issues. At the Jakarta warehouse at 2 a.m., simplicity trumps complexity.

Long term reliability

Industrial IoT devices are not smartphones that are replaced every few years, but assets that need to operate reliably for 5-10 years or longer. The eSIM standard is still evolving, network support varies by region and operator, and backward compatibility is not guaranteed. In contrast, physical SIM connectors have a decades-long proven track record of reliability, and the current standard will be equally valid for the next decade.

Harsh Environment Adaptability

The Nano SIM connector is a purely mechanical passive component with no risk of firmware failure, no protocol negotiation issues, and no remote configuration errors. In vehicles that experience continuous vibration or sensors that are subject to 100°C temperature fluctuations, this simplicity becomes a feature rather than a limitation.

Cost and Control Advantages

For manufacturers with an annual output of thousands or even tens of thousands, integrating a reliable SIM connector into the design is both straightforward and economical. The supply chain is mature, the test protocol is perfect, and the failure mode is clear. The eSIM infrastructure requires carrier relationships, provisioning systems, and ongoing management overhead, a complexity that is not cost-effective for most industrial applications.

Operational autonomy

The physical SIM card gives the operator direct control. When the device is abnormal, the network performance drops or the operator relationship changes, the replacement SIM card provides an immediate solution. In an industry where downtime costs thousands of dollars per hour, this on-the-ground flexibility is extremely valuable.

Intelligent diagnosis function

A new generation of connectors is integrating self-diagnostic capabilities that can predict maintenance needs and warn of potential connection problems in advance.

5G/6G network support

In response to the demand for higher data rates in IoT devices, SIM connectors are evolving to support a new generation of cellular network standards.

Standardization and compatibility balance

Physical SIM standards (2FF, 4FF) ensure backward compatibility and long-term reliability, while eSIM continues to grow in the consumer market, creating a complementary technology ecosystem.

In the context of the global deployment of IoT devices, choosing the right supplier of electronic components is as important as choosing the technology.BonChipAsProfessional distributor of electronic componentsIn the SIM connector field:

Full product line supply

It covers mainstream Mini SIM and Nano SIM connectors, as well as special specifications and customized solutions to meet the precise needs of different customers.

Quality Assurance System

All connectors are sourced from authorized manufacturers with complete quality traceability and reliability guarantees.

Rapid delivery capability

With a global warehousing network and an optimized logistics system, we ensure the rapid availability of urgently needed materials for our customers.

Technical Support Services

A team of professional engineers provides selection guidance, design optimization and fault analysis support to help customers improve product reliability.

When your next IoT device design requires that kind of "forget about it" connection reliability,BonChipoffers you access fromComponent selection to batch supplyFull process support. We understand that in mission-critical applications, the reliability of each component is critical to the overall performance of the system.