As an engineer of outdoor equipment or industrial products, it is estimated that there is no less headache for waterproof and dustproof. There is a group of data in the industry: more than half of outdoor and industrial equipment failures are not actually the problems of the circuit itself, but are damaged by water vapor, dust, temperature difference or daily cleaning. Therefore, when drawing and selecting the type, the first thing we have to think about is: does this thing need IP67, IP68 or IP69K?

But don't go into a misunderstanding, think "the higher the level of protection, the better". If the selection is high, the cost will rise and the design will become complicated. If the selection is low, the product will be returned or "strike" at the scene. Today, I combine.ATTENDSome of our practical project experience has broken up these common IP grades to help you feel more confident in the next selection.

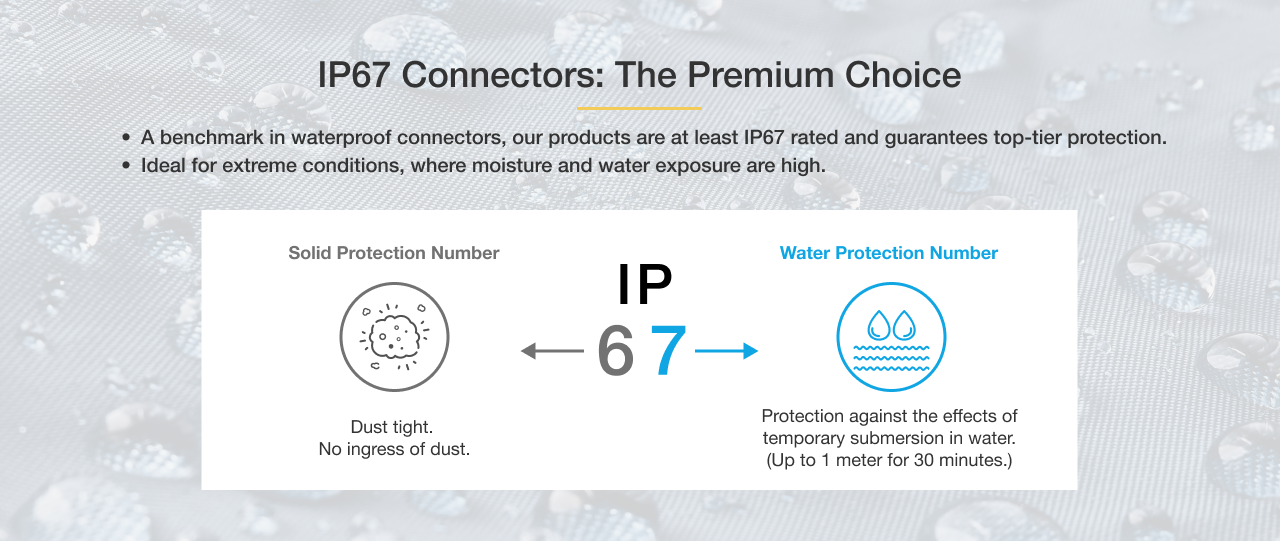

IP is the abbreviation of "Ingress Protection" (protection level), followed by two numbers, is the International Electrotechnical Commission (IEC) in the standard IEC 60529 rules.The first number is anti-solid (such as dust), the second number is anti-liquid (mainly water). The key point is that these two numbers represent completely different test conditions. It is not simple. The larger the number, the better.

Dust (first digit)For us to do industrial equipment, generally at least to see "5" or "6". IP5X is "dust-proof", allowing a small amount of dust to enter but does not affect the work; IP6X is "dust-tight", a little dust can not enter. Production lines or outdoor environments are usually designed according to IP6X to be safe.

Waterproof (second number)There are many doorways here. The three levels we deal with most often are:

IPX7: Immerse the product in 1 meter deep water and soak for 30 minutes.

IPX8: Continuous immersion with harsher conditions than IPX7, but the specific depth and duration of soaking need to be agreed between the manufacturer and the customer.

IPX9K: Use a high-temperature high-pressure water gun to "violently" flush at close range. This is mainly based on another standard, ISO 20653.

Many people struggle with IP67 or IP68 when selecting models, and feel that 68 is definitely better than 67. It's not that simple. The core difference is"Are the test conditions fixed or talKable"。

IP67: The standard is clear and not negotiable.

Its test conditions are written in black and white in the standard: 1 meter water depth, 30 minutes. So, when a product is marked IP67, you know that it can definitely withstand the soaking conditions. This is very suitable for those who may be caught in the rain, or occasionally a short period of water (such as outdoor Internet of things devices, surveillance cameras, handheld terminals).

IP68: condition floating, must ask clear

The standard only says that it "protective performance is stronger than IP7", but how much stronger-is it soaked in 1.5 meters for 1 hour or 3 meters for 3 days. So, just look at the "IP68" these three words, the amount of information is almost zero. The actual protection capability of IP68 claimed by different manufacturers may vary greatly.

To design a real IP68 product, it is usually necessary to use better sealing materials (such as fluorine rubber O-rings), thicker sealing structures, and stricter air tightness testing during production. Simply put, IP67 is the "standard answer" and IP68 is the "custom answer". When you are selecting the type, you must ask the supplier to provide the specific test water depth, time and verification report corresponding to their IP68 grade, otherwise the IP68 label has little reference value.

Experience: when IP68 is required, it must be clearly written in the technical agreement: "IP68 in this project is defined as soaking in x meters deep (light/salt) water for y hours". Otherwise, the notation almost loses its meaning. When ATTEND cooperated with us, for the underwater sensor project, it clearly defined IP68 as "3 meters deep, 48 hours, fresh water environment" and provided a complete test report.

IP69K is derived from the automotive industry standard (ISO 20653) and is designed for equipment that needs to withstand high-pressure, high-temperature steam cleaning, commonly used in food processing and construction machinery. Its test is to use a high-pressure water gun (80-100 bar) at 80-100°C, and spray from all angles at a very close distance (10-15cm).

There is a big myth here: IP69K is not equal to or better than IP67/IP68. It only proves that it can withstand high-pressure spray washing, but it cannot guarantee that it will not enter water for a long time in still water. If your equipment requires high-pressure flushing and may be soaked in water, you must look for dual-certified products clearly marked "IP69K & IP68.

There is a very important pit here: IP69K does not mean that you can soak in water!

Unless the product is also marked "IP67/IP69K" or "IP68/IP69K", a product that only passes the IP69K test may not be able to resist long-term immersion in still water. Because high pressure injection and hydrostatic pressure are two completely different physical challenges. For IP69K products, multiple seals such as double O-rings and one-piece injection molding are often required, and the material and process requirements are extremely high.

Talking on paper is boring, and it is clearer to see it in combination with specific products. For example, in the field of industrial automation, commonly used M8, M12 series connectors, ATTEND will generally make IP67 or IP68 grade. These joints on AGV trolleys and mechanical arms have to deal with oil pollution, splashing water, vibration, and frequent plugging and unplugging. Therefore, their metal thread locking structure will be equipped with O-rings, and the cable outlet will be covered with glue to customize the specific test conditions of IP68 according to the possible water depth at the customer's site (such as when the equipment is cleaned).

For example, many outdoor charging piles and industrial handheld terminals now like to use waterproof magnetic connectors (such as magnetic Pogo Pin). The advantages of this structure are convenient "blind insertion", large alignment tolerance, and not easy to damage the seal because it is not inserted properly. ATTEND will pay special attention to the sealing cooperation between the needle holder and the shell, the deburring of metal parts (to prevent scratching the sealing ring), and the injection molding consistency of the cable assembly to ensure the overall IP67/68 protection. As a long-term partner of ATTEND, BONCHIP can not only provide standard models when supplying such high-protection connectors, but also help customers quickly obtain customized samples. Their inventory and logistics response are well evaluated in the industry, which can help the research and development team to seize valuable time.

Misunderstanding: think IP68 must contain IP66 (strong water spray) ability.

Fact: Not necessarily unless the product is clearly marked "IP66/IP68" and passes both tests. Anti-splash and anti-soak are two sets of tests, not included in the relationship.

Misunderstanding: waterproof is equal to anti condensation.

Fact: IP test only cares about "the water outside does not come in" and does not care about "the air inside condenses into water droplets". To prevent condensation, we have to think of ways in the structure, such as adding a vent valve, making internal potting, or reducing the temperature difference between the signal line and the cavity.

Myth: My mobile phone is marked with IP67, so I can take it swimming casually.

Reality: The IP67 test is static and mild. Changes in water pressure during swimming, arm strokes, and chemicals in the pool can all cause the seal to fail. Moreover, if the mobile phone is used for a long time, the sealant will age and may also affect the air tightness. So, don't be too superstitious, water is generally not warranty.

Indoor consumer electronics devices usually only need to achieve IP54 protection to provide basic splash water protection. General outdoor equipment should be at least IP67 standard to cope with rain and accidental flooding.

Equipment exposed to the outdoors for a long time, such as surveillance cameras or communication base stations, should be selected for IP67 or IP68 protection, because these equipment needs to resist continuous moisture erosion and ultraviolet aging. Underwater equipment must have a degree of protection of IP68, but the depth and duration of immersion must be clearly specified.

Food processing equipment, construction vehicles and agricultural machinery that require high-pressure hot water cleaning must choose the IP69K standard. Outdoor charging stations are usually designed with IP67 or IP68 protection, because the charging process involves high-frequency plugging, magnetic mechanism operation and rain.

The blind pursuit of high protection level is a common cost waste. Based on the hundreds of cases ATTEND has served, I have summarized this quick look-up table for selection:

| Application Scenarios | Recommended IP Level | Core Considerations and Key Points of ATTEND Scheme |

|---|---|---|

| Indoor Electrical/General Equipment | IP54 | Anti-daily dust and splash water can be. The focus should be on cost control and thermal design. |

| General outdoor equipment (camera, internet of things terminal) | IP67 | Cope with rain and brief standing water. ATTEND's M12 connectors are sealed with an O-ring and one-piece injection molding process for excellent reliability in such scenarios. |

| Long-term outdoor/underwater equipment (Base station, dock sensor) | IP68 | The depth and time must be clearly defined with the supplier. ATTEND can customize IP68 conditions for customers, using fluorine rubber seals and more stringent air tightness tests. |

| High pressure clean environment (Food Machinery, Agricultural Equipment) | IP69K or IP69K & IP68 | Structural design is key. ATTEND's solution uses double seals, high-temperature resistant materials and high-strength mechanical latches. |

| Frequent plug interface (Outdoor charging pile, industrial handheld terminal) | IP67 / IP68 | Wear resistance and alignment accuracy are equally important. ATTEND's waterproof magnetic connector reduces alignment wear, and its IP67 version has proven high cycle life on shared charging devices. |

Myth: "IP68 must be better than IP67"

Wrong. As mentioned earlier, the IP68 condition is not clear is empty talk. A "IP68(1.5 m/30 minutes)" product, its diving ability is not much stronger than the standard IP67.

Misunderstanding: "Passed the IP69K test, soaking in water is no problem"

Wrong. These are two very different tests. Do not mix unless the product is clearly labeled with two-factor certification.

Misunderstanding: "choose IP68, do not need to worry about condensation"

Wrong. IP prevents the intrusion of external liquid, but it cannot prevent the condensation water generated by the temperature difference inside the equipment. Solving condensation requires an independent breathable design or internal gluing.

Misunderstanding: "The equipment is marked IP67, so I can swim with it"

This is a typical user misunderstanding. IP67 is ideal for laboratory testing, while swimming involves dynamic water pressure, chemicals (chlorinated water) and a depth that may exceed 1 meter, which is extremely risky.

AsAuthorized Distributors of ATTEND,BONCHIPThe value brought to us is far more than just supply. In the cooperation with their technical team, there are two deep experience:

One is the "professional understanding" ability. They can quickly translate our vague scene descriptions (such as "equipment is installed at the dock, often splashed by waves, and washed with a high-pressure water gun once a month") into accurate IP rating recommendations and ATTEND's specific product models, avoiding the disconnection between specifications and field requirements.

The second is the guarantee of "sample is mass production". They provide test samples, the sealing process and materials are exactly the same as the batch supply. We have done comparative tests. The sealing ring material and assembly accuracy of IP67 connector samples obtained from BONCHIP channels are no different from those of products delivered in large quantities in the later period, which ensures the effectiveness of the design verification stage.

In addition, their inventory and logistics response also gave us "reassurance" when the project was urgent ". Once the production line equipment was in urgent need of upgrading the waterproof interface, BONCHIP delivered the required specifications of ATTEND M12 connector to our factory within 48 hours, ensuring zero delay in the production line transformation.

Choosing IP protection level is essentially buying a precise "insurance" for the "living environment" of the product ". Underinsurance brings risks, and overinsurance wastes costs. My suggestion is to involve a vendor technical team like BONCHIP early in the design process to jointly define requirements based on the real-world environment. After all, true reliability comes from a deep understanding of details and precise control.